This was my first ever metal working project. My wife wanted a studio roller for the kitchen, so I got to it - thanks for watching! Designed in SketchUp for free.

SketchUp file for download can be found here.

Thanks for checking out the article and video!

MATERIALS

1" 16 Square Gauge Steel

1 1/4" 12 Gauge Flat Steel

8/4 Walnut Wood + Wipe on Polyurethane

5/8" All Thread + Nut Wood Screws

TOOLS

Lincoln PowerMig 210: https://amzn.to/2ECMLjl

SAWSTOP Contractors 30” Saw: https://amzn.to/2Luh91q

Table Saw Sled: https://amzn.to/2t2qVjD

13” Thickness Planer: http://amzn.to/2u7YrmK

6” Jointer: https://amzn.to/2Y7THgb

Impact Driver: http://amzn.to/2q1l5wn

Drill Press: https://amzn.to/2GjgOjh

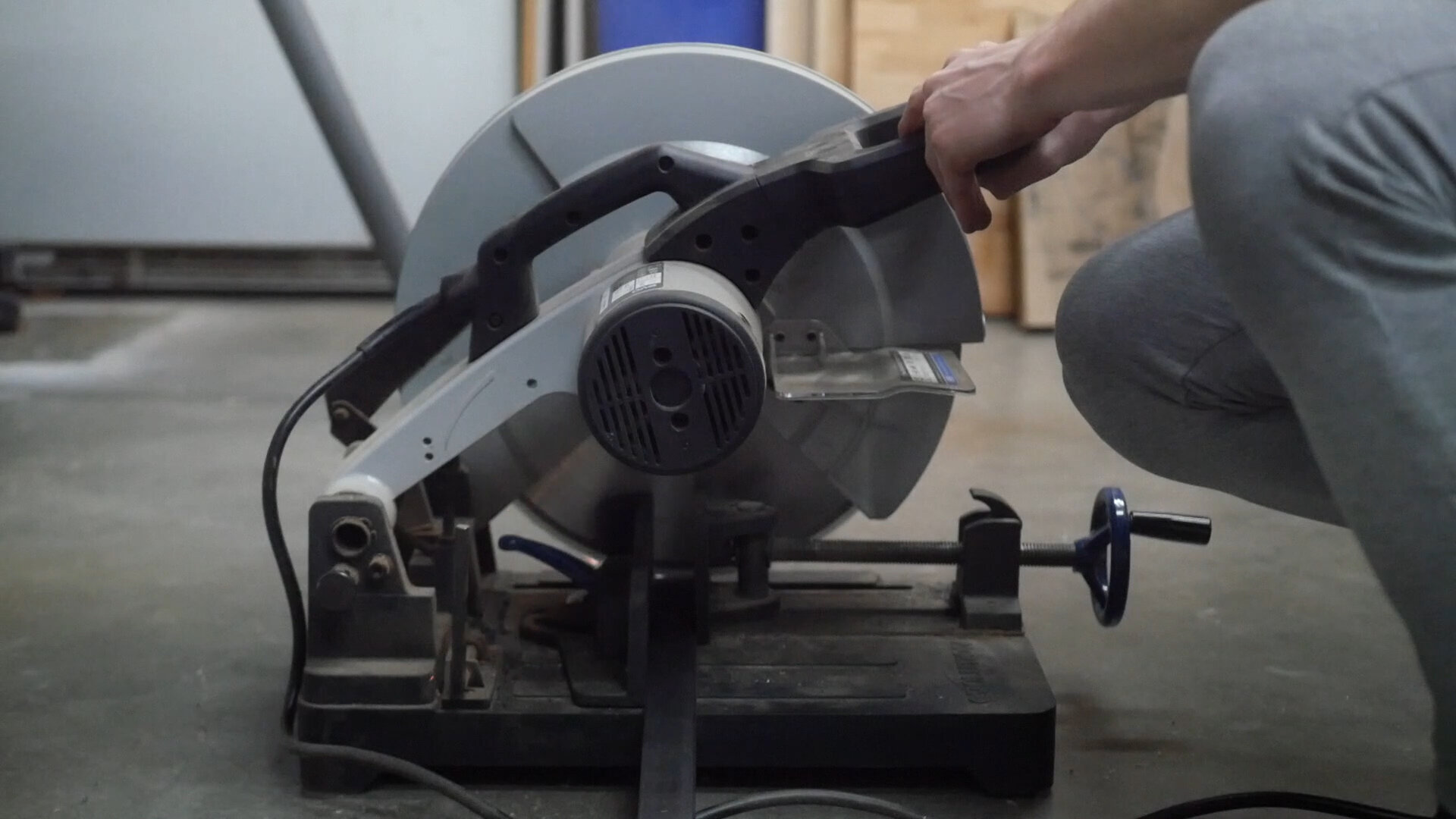

Metal Chop Saw: https://amzn.to/2HNowU4

Digital Caliper: http://amzn.to/2p360xg

Angle Grinder: https://amzn.to/2FhtDLe

Flap Discs, Grinding Wheels, Cutting Wheels

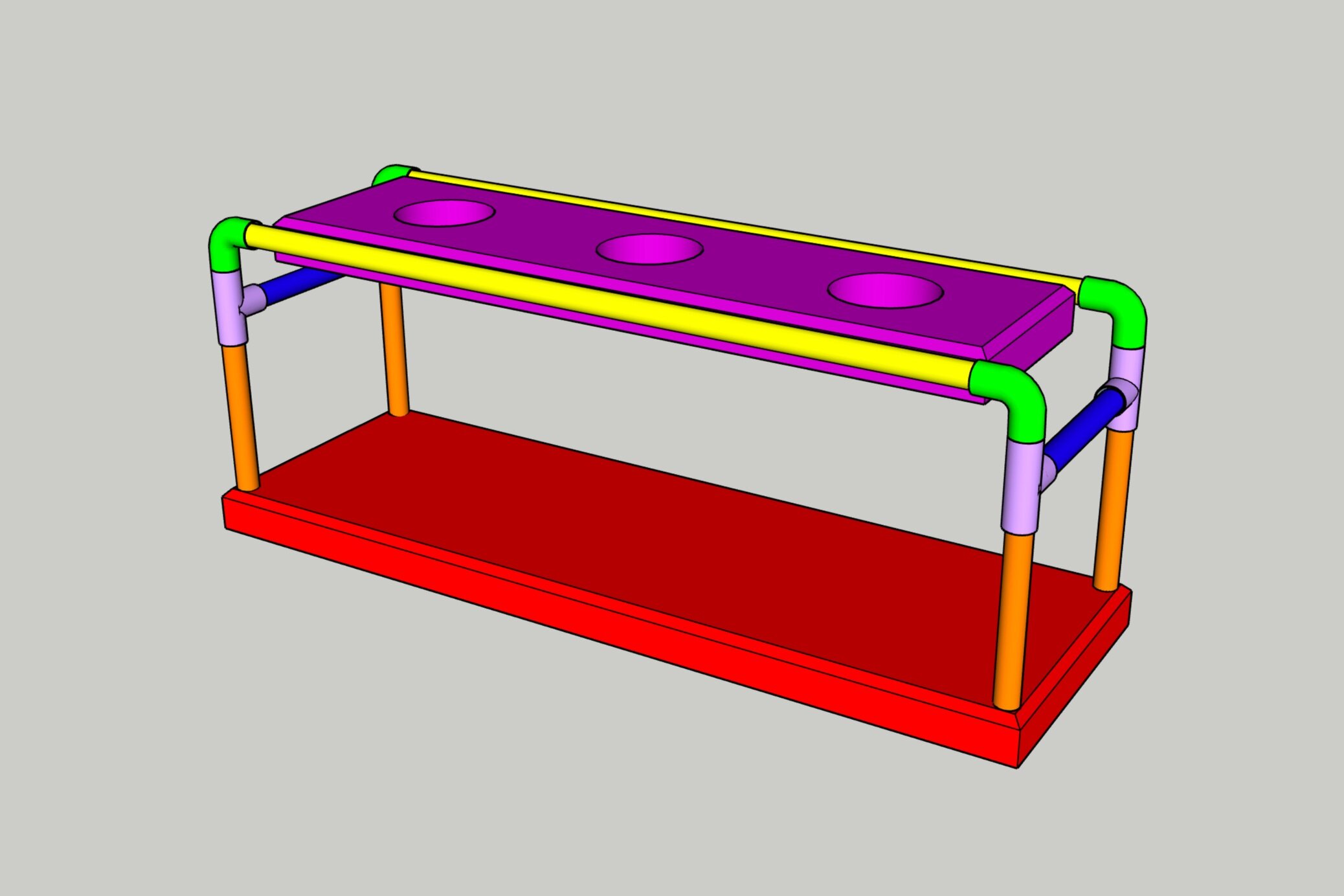

After some careful research and doing some practice welding, my wife and I settled on a design for our studio roller. Above is a Sketchup render of the steel portion of the build.

The key thing for me was to understand the complimentary angles to create so all of my welds looked seamless.

The first set of steps were just a series of measuring, marking, and breaking down the square steel tubing I had. I was as precise about this as I could be - the chop saw really helped. An angle grinder also works for cutting, it just might be a little less precise. Just take your time - measure many times and cut once.

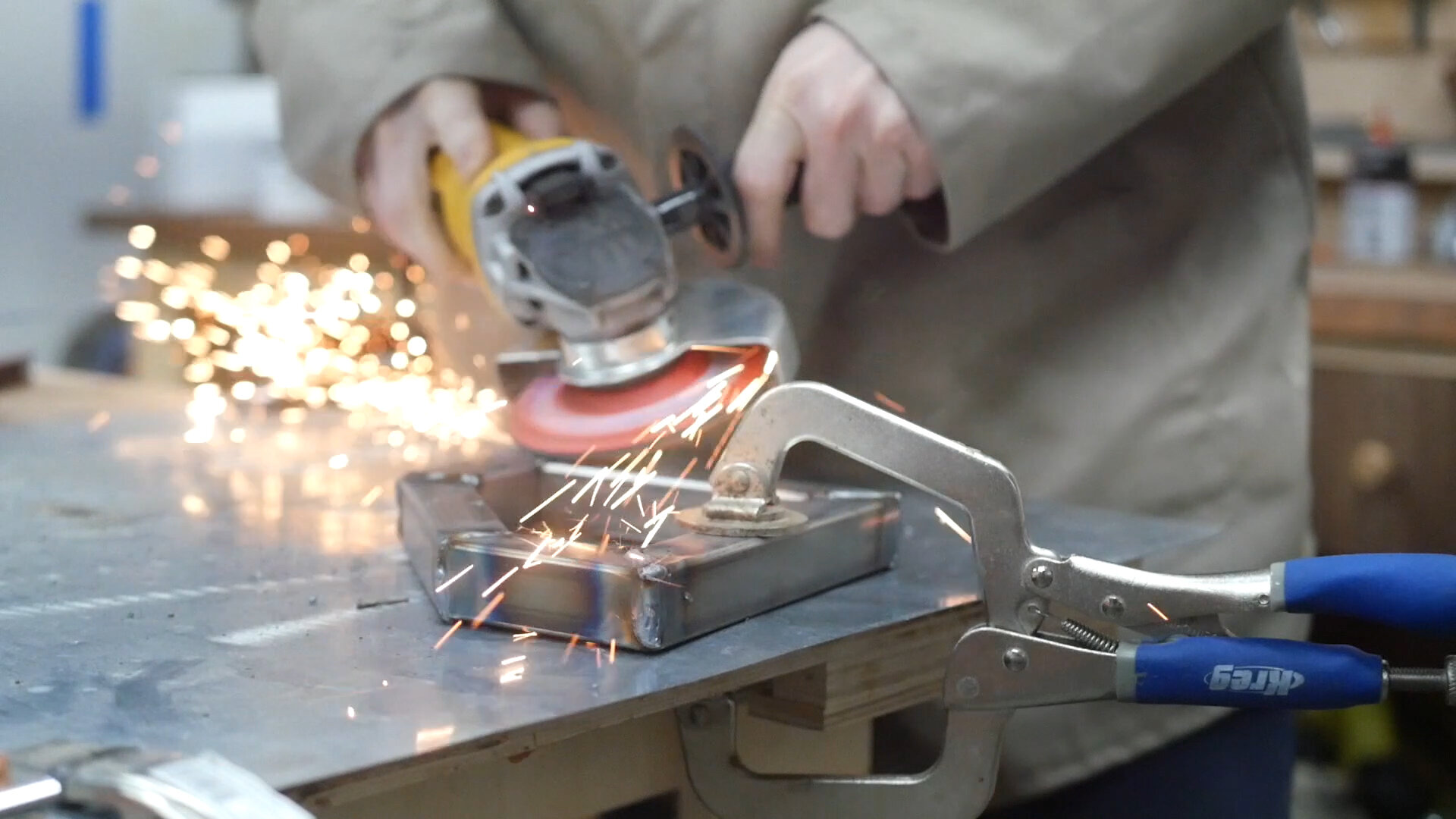

In preparation for welding, I used my flap disk to grind down each surface that would be welded. This will get rid of any burrs left over from the cuts, as well as add a small bevel that allows your welds to penetrate the seams. Having a belt grinder would be the fastest way to knock out all of this prep work.

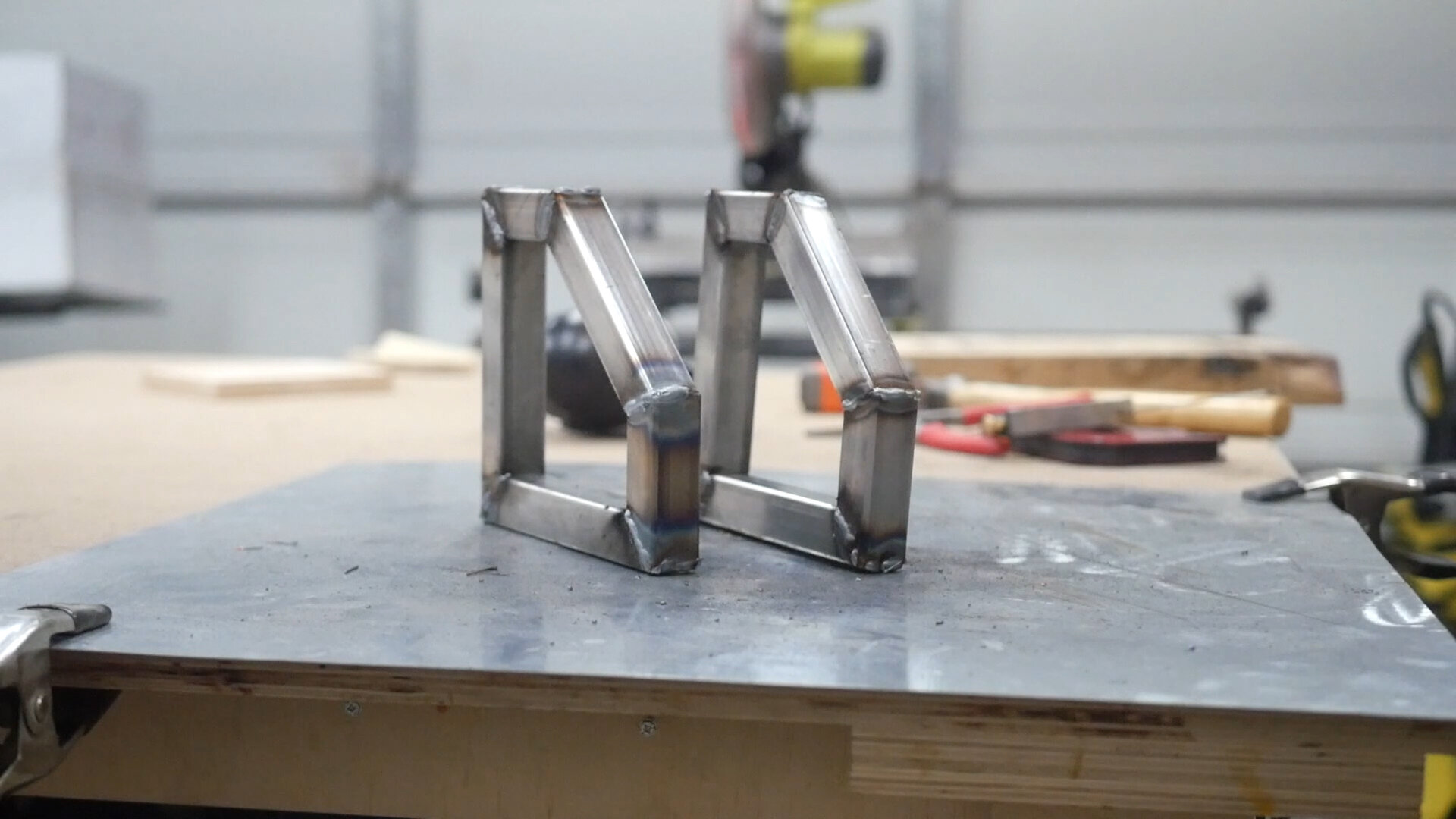

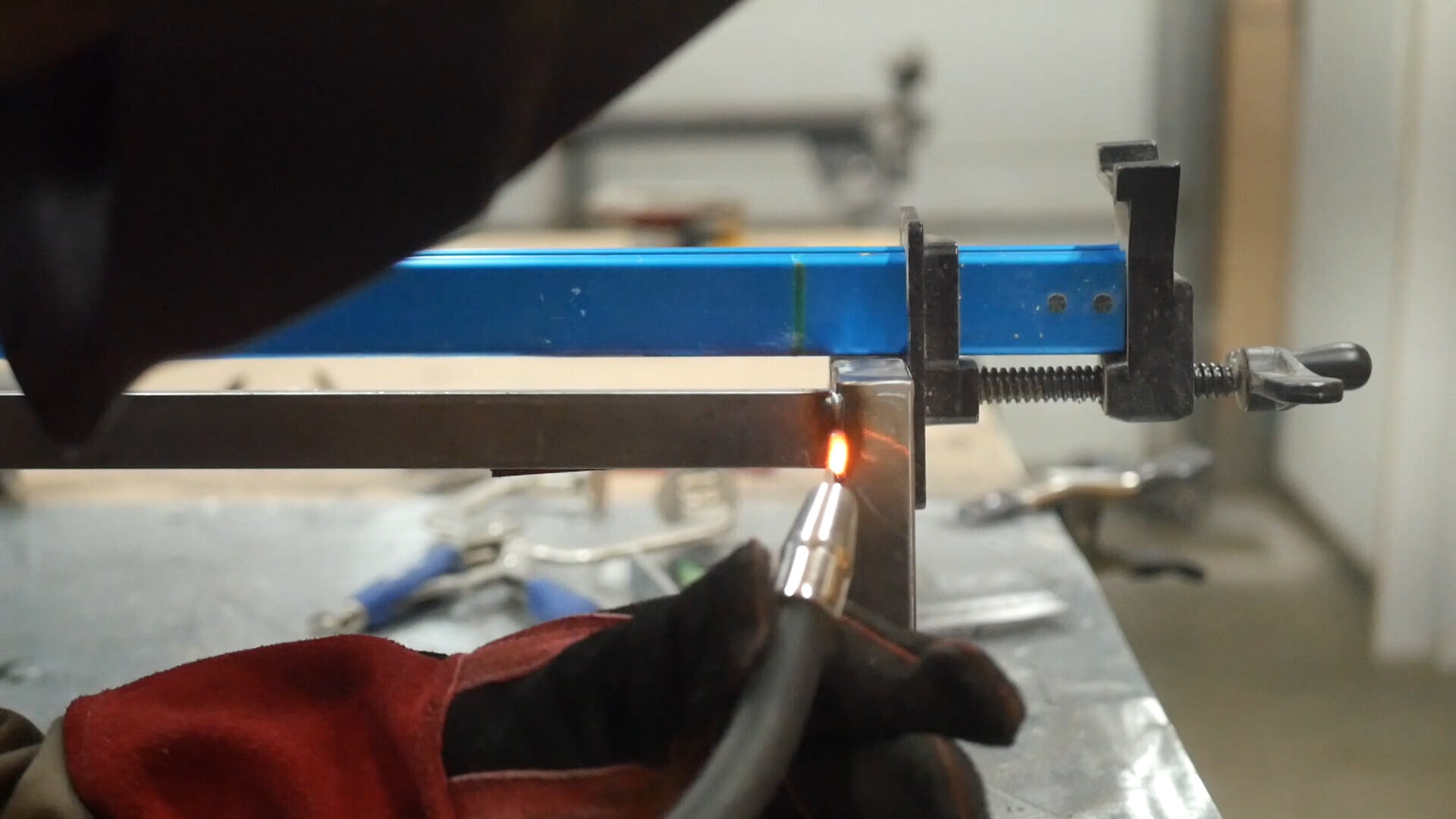

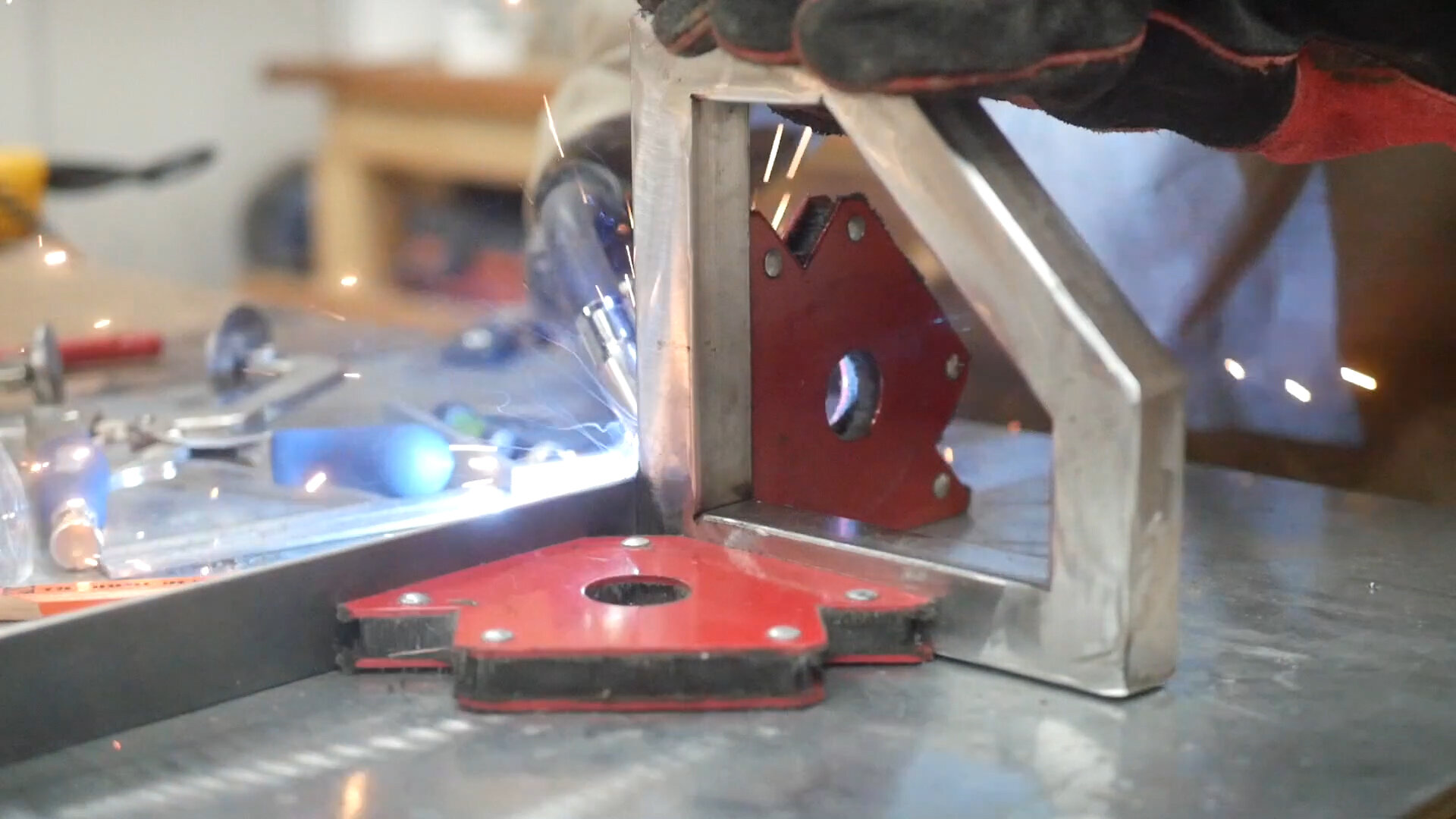

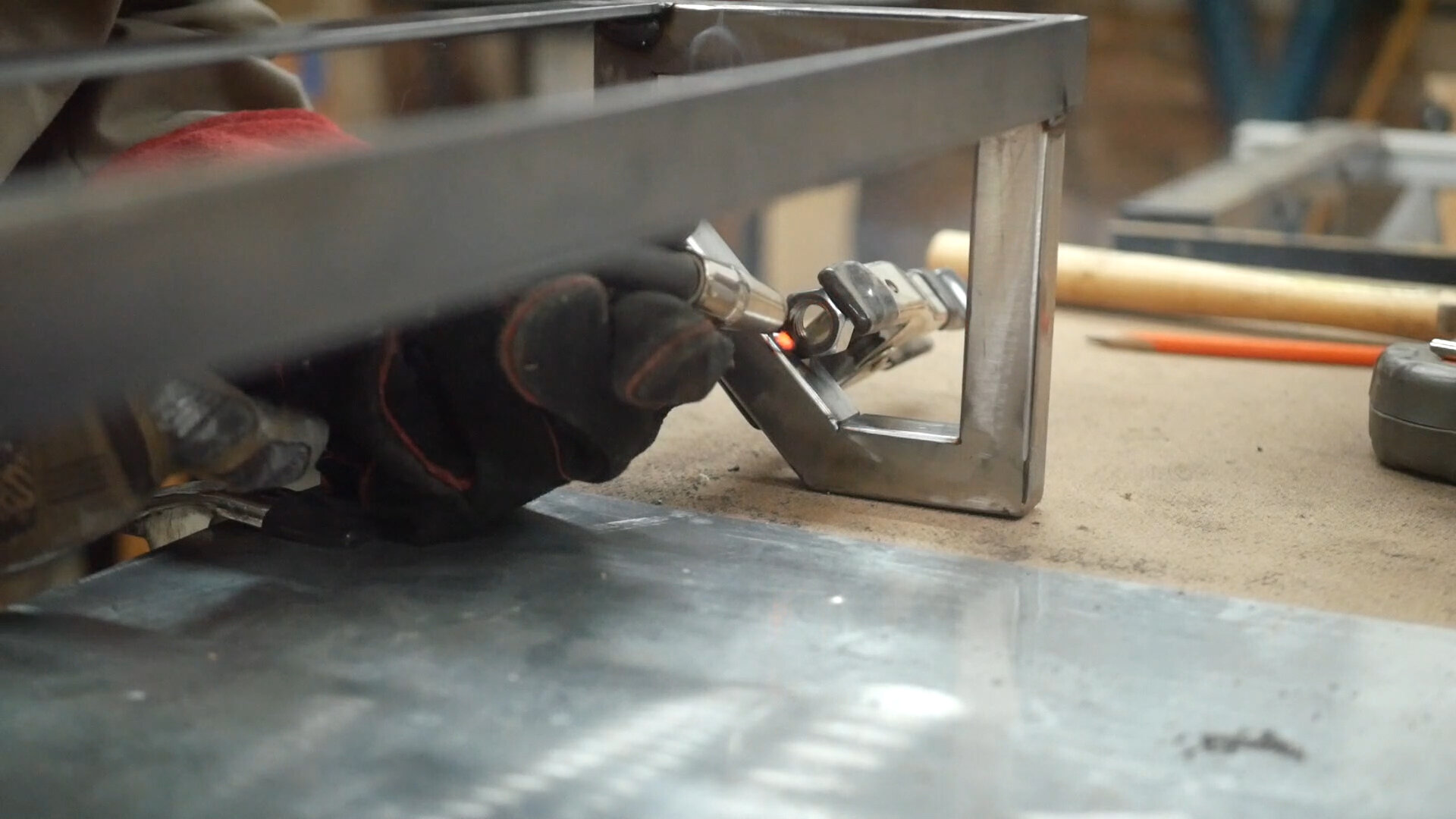

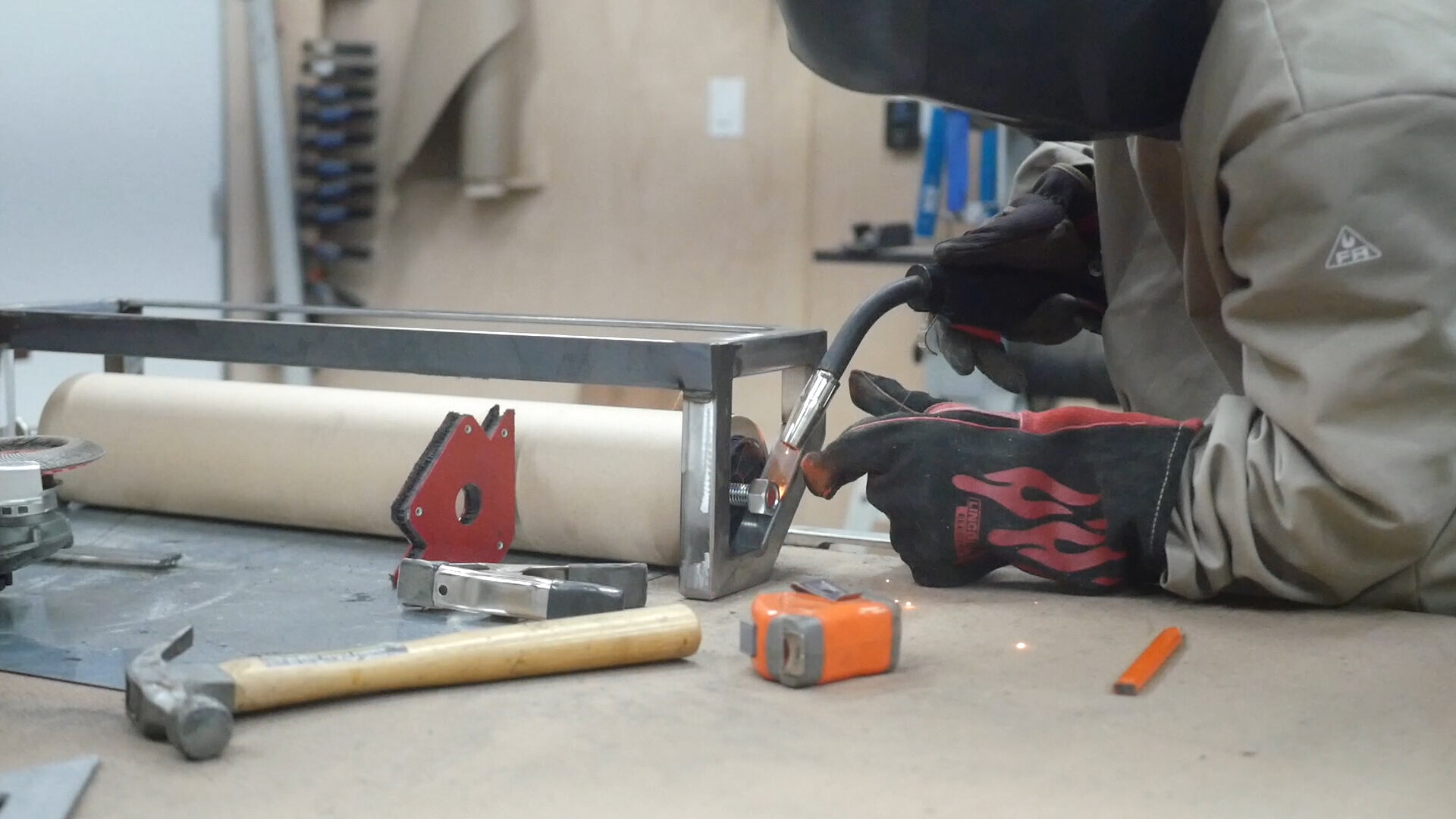

Next, it was time for welding. I don’t currently have a welding table, but using a series of magnets and clamps allowed me to tack each piece in place properly, then come back and add full welds. You don’t want to put too much welding heat in one place as it will cause the metal to warp. A welding table with lots of clamps can help prevent this.

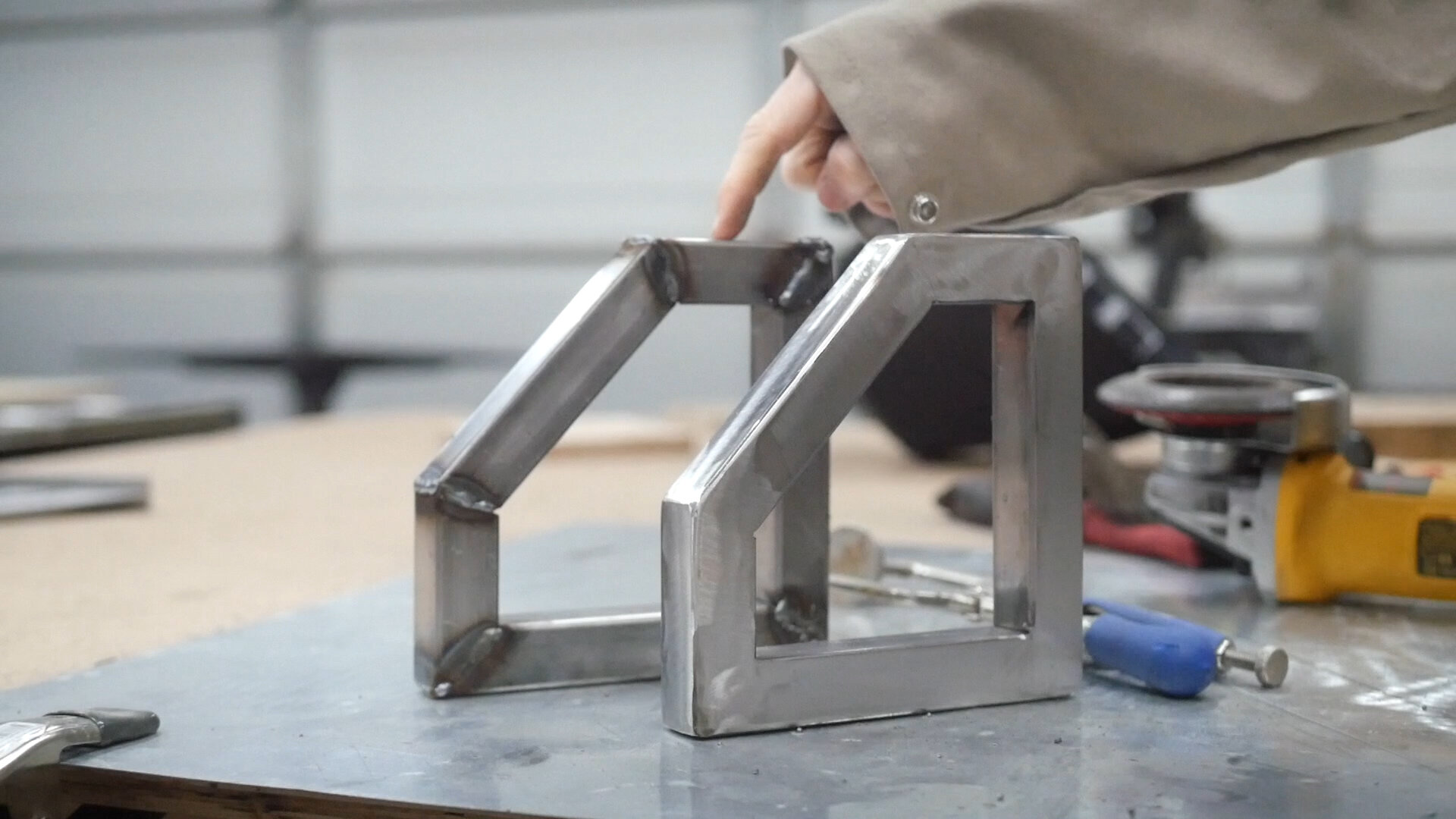

Once the welds were all in place, I could go back with a flap disk again and grind them down flush. You can see the difference in the the before and after in the last photo.

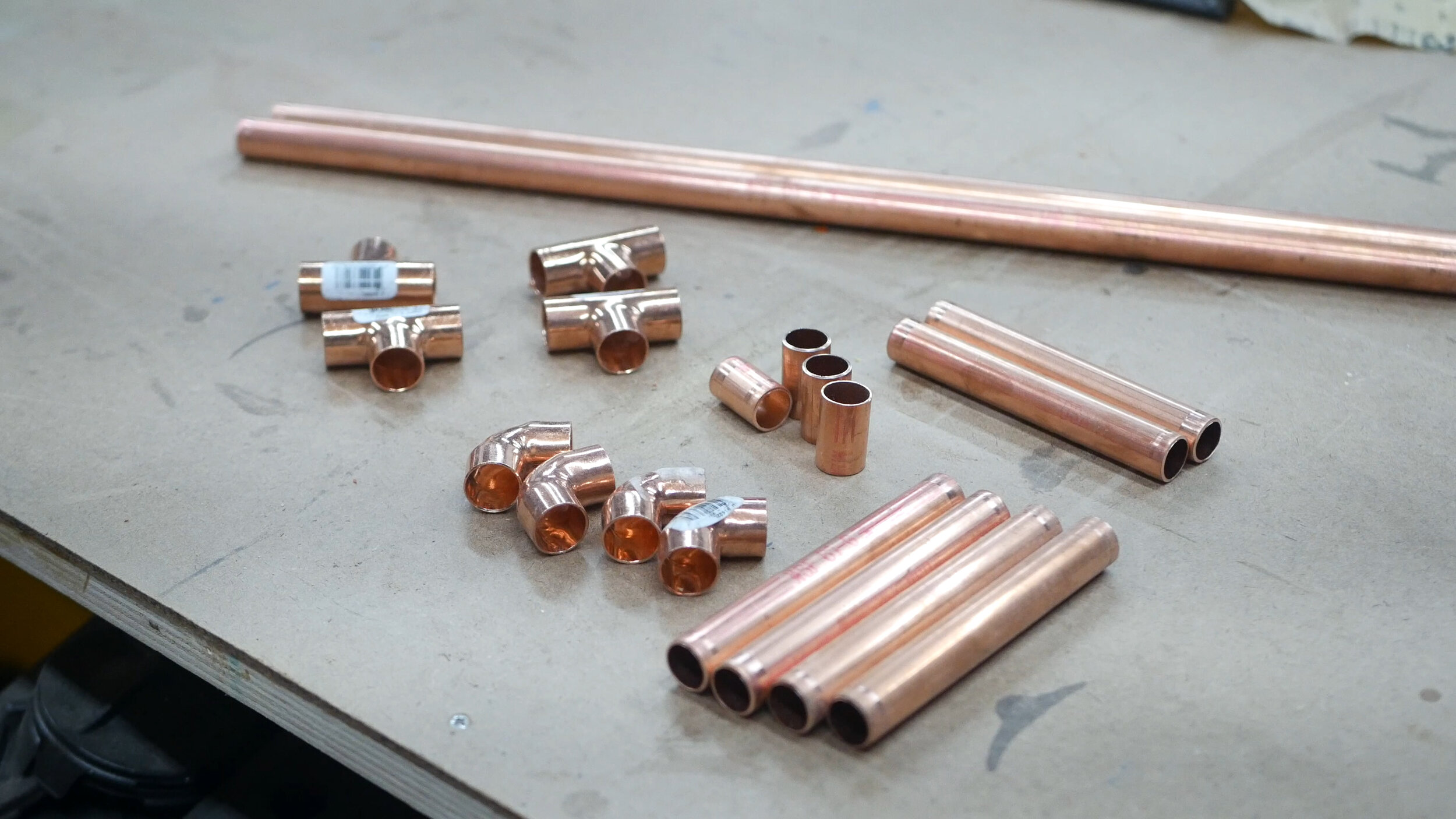

Once each of the main pieces were ground down, I could move on to connecting them with some flat bar stock. This is an important step - since you won’t be able to adjust the width of your studio roller, make sure you are sure of how wide you’ll want your final piece to be. We chose 24” after experimenting with some different widths. I cut down the flat stock and welded the pieces together.

There was one piece on top and one piece on the back, the latter of which eventually would connect the piece to the wall.

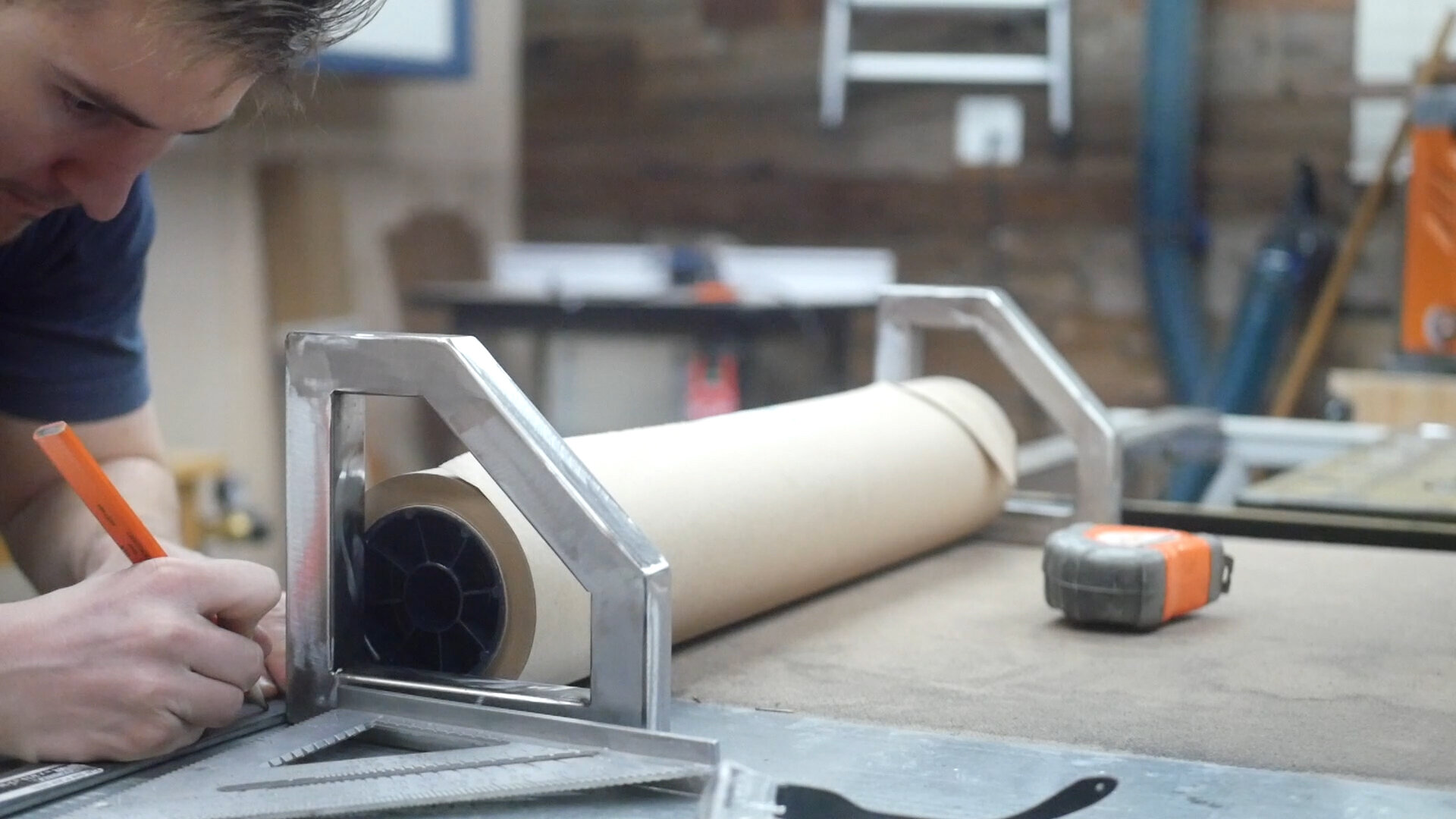

My plan to attach the roller to the main frame was to use all-thread and welded nuts. That way, I could untwist when the roller was empty and replace it. To do this, I welded on a steal nut to the framing on one side, and welded on a corresponding flat piece of steal on the other side so the all-thread could rest on it. I then could cut it to length on the chop saw. This was really straight forward - I just took my time and used the paper roll as a reference as it allowed me to confirm it would rest/hang at the right level.

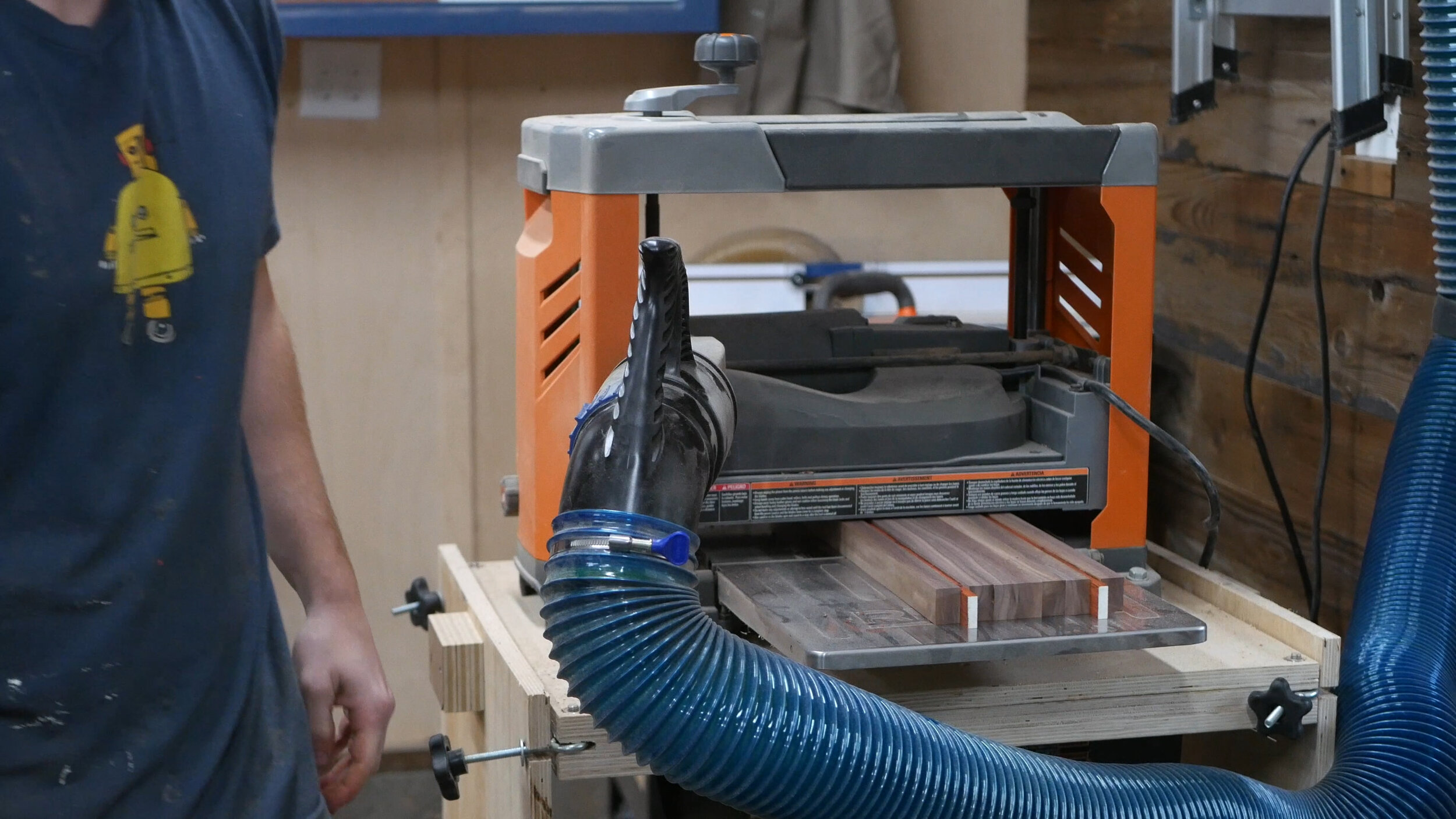

At this point, I was done with metal working. We have floating walnut shelves in the kitchen, and I wanted the wood portion of the build to match those shelves. Plus, I had left over walnut.

This was relatively simple - using the framing of the structure, I measure and marked the length and width of the walnut, and then milled it down using a combination of my jointer, planer, and table saw. I then could sand down the edges and apply a wipe on polyurethane to finish it off.

To hang the roller on the wall - we took it into the kitchen to figure out where we wanted it. We we then could go back to the shop and drill pilot holes in the steel - both for the holes for the wall and the holes that would allow me to attach the walnut - this was a mix of my drill press and power drill. Once we had that ready to go, we could take it back to the kitchen to choose the exact height we wanted.

From there, I could drill pilot holes and add in anchors to the wall (no studs), and then drill in a single screw to attach. I then could check for level and drill/anchor in the second hole. This felt very sturdy against the wall! Last up, I added the walnut to the top of the piece using the remaining pilot holes I had drilled previously in the shop.

The last step was to cut to length and hang two pieces of flat steel that would help keep the piece of paper from the roller against the wall. Once would go up top, one would go at the bottom. I cut these to length on the chop saw one more time and ground down the sharp edges. I then drilled two holes at the drill press to accept screws.

My method for this was to use one screw and two washers up against the wall to allow the steel to not sit totally flush with the wall. That way, the paper could slide more easily behind it, but still be pressed mostly up against it. The steel wasn’t even sharp, but to my surprise, it was enough that I could use it to rip the paper quickly when we wanted to replace it.

And then I was done! The wife and I love it and it’s a lot of fun to draw on each month. We’ve had it for about a year now and have barely even started making our way through this first roll of butcher paper - so if you’re worried about waste, just know that your use will be minimal and it really adds something to the kitchen space.

Check out the video to see this thing in action on my YT channel!

See you around!

Zach